NSGAFÖU - Die flexible Gummiaderleitung

Flexibilität und Robustheit, zwei Eigenschaften, mit der das NSGAFÖU Gummikabel für eine sichere Verbindung sorgt. Der Kabelaufbau und die Produkteigenschaften sorgen dafür, dass sie auch bei thermischen Belastungen und äußeren Umwelteinflüssen ihre Widerstandsfähigkeit erhalten. Zum Einsatz kommen sie unter anderem in Rohren und geschlossenen Installationskanälen. Dabei können sie durch die Anordnungen aus Aderleitungen nach VDE 0250 Teil 602 gebündelt oder zum Anschluss bewegter Teile installiert werden. Sie eignen sich mit einer Nennspannung von 1,8/3 kV besonders für eine kurzschlusssicher und erdschlusssichere Verlegung. Das NSGAFÖU Kabel von Lapp kommt in vielen Anwendungen zum Einsatz wie beispielsweise in Schaltanlagen, Bussen, Schienenfahrzeugen oder in Verteilern.

Bedeutung der Typenbezeichnung NSGAFÖU

Der Buchstabe N steht dafür, dass es sich bei der NSHÖU Leitung um eine genormtes Leitung handelt. Das S steht für Schnur und dafür das es sich beim Außenmantel um eine Segeltuchhülle handelt. Dadurch ist die die NSGAFÖU Leitung robust und hält selbst schweren mechanischen Beanspruchungen stand. Der Buchstabe G steht für Gummihülle wodurch die Aderleitung für erhöhte Temperaturbereiche geeignet ist. Das A steht einfach nur für Ader bzw. Aderleitung. Der Buchstabe Ö steht für ölbeständig und das U für flammwiedrig.

Das Aderkabel NSGAFÖU lässt sich wie folgt übersetzen:

- N – genormte Leitung nach VDE 0280 T.602

- S – Schnur sowie Material des Außenmantels Segeltuchhülle

- G – Gummihülle als Außenmantel und Aderisolation

- A – Ader/Aderleitung

- F – Leiterart; feindrähtiger Leiter

- Ö – ölbeständig

- U – unentflammbar/flammwidrig nach VDE 04822-332-1-2 / IEC 60332-1-2

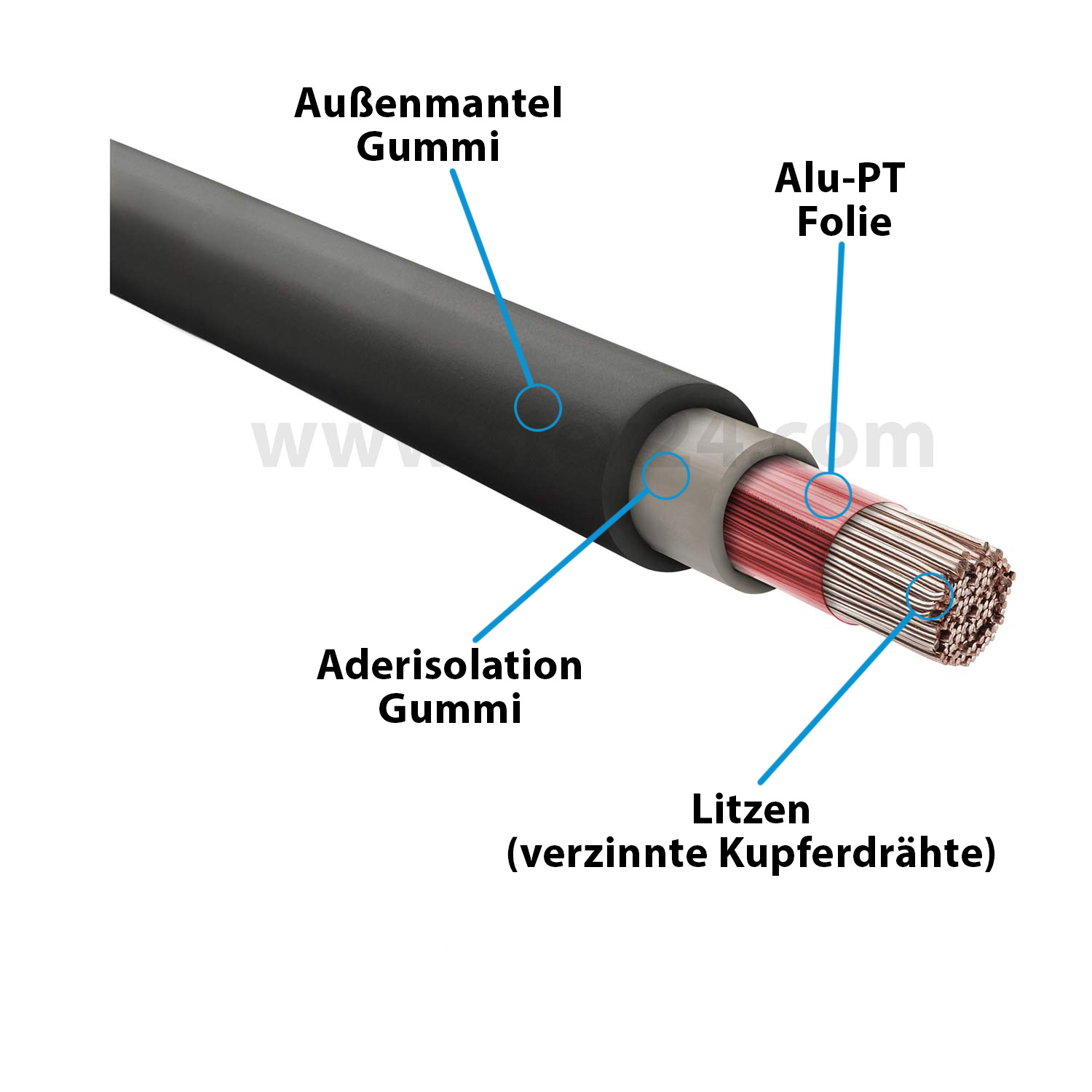

Die NSGAFÖU Gummileitungen als zuverlässige Verbindung

Im Aufbau besteht die kurzschlussfeste Gummiaderleitung aus feindrähtigen verzinnten Kupferlitzen. Durch das Material des Außenmantels, eine Polychloropren Gummimischung (5GM3) hält die Leitung selbst schweren mechanischen Beanspruchungen stand. Die Aderisolation besteht aus einer Gummihülle, eine spezielle Gummimischung ohne Farbzusätze – so ist das Kabel für Anwendungen mit hohen Temperaturen geeignet. In Bewegung beträgt die zulässige Außentemperatur -25° C bis 80° C, fest verlegt liegt der Temperaturbereich zwischen -40° C und 80° C. Der Einsatz eignet sich daher für flexible Anwendungen ohne Zwangsführung und ohne Zugbelastung in trockenen Räumen. Ist keine Brandabschottung vorhanden, ist keine direkte Erdverlegung erlaubt. Der Mindestbiegeradius von bewegt 10,0 x Außendurchmesser und fest verlegt 6,0 x Außendurchmesser sorgt für eine flexible Verlegung des Lapp NSGAFÖU. Im Brandverhalten sind die Leitungen flammwidrig nach IEC 60332-1-2 und selbstverlöschend sowie weitgehend ölbeständig.

Anwendungsgebiete der Gummiaderleitung NSGAFÖU

Die kurzschlussfeste Lapp Gummileitung NSGAFÖU gilt in Niederspannungsanlagen bis 1000 V als kurzschluss- und erdschlusssicher und gewährleistet eine Verlegung nach VDE 0100 Teil 520 und VDE 0298 Teil 3. Zum Einsatz kommt es als zuverlässige Verdrahtung an Maschinen, bei öffentlichen Verkehrsmitteln wie Schienenfahrzeugen und im Fahrzeugbau beispielsweise in Omnibussen sowie bei schaltschrankinternen Verdrahtungen und Geräteverdrahtungen. Es wird ebenso eingesetzt, um eine Verbindung zwischen Verteilerstromkreisen und nachgeschalteten Überstromschutzeinrichtungen herzustellen.

Was gibt es noch für Kabeltypen im Bereich Gummileitungen

| Kabeltyp | Nennspannung Uo/U | Besonderheit |

|---|---|---|

| H01N2-D | 100/100V | Schweißleitung |

| H05RN-F | 300/500V | |

| H05BQ-F | 300/500V | PUR-Mantel |

| H07RN-F | 450/750V | |

| H07BQ-F | 450/750V | PUR-Mantel |

| H07RN8-F | 450/750V | Bis 10m Wassertiefe |

| NSSHÖU | 600/1000V | extrem Robust |

| NSGAFÖU | 1,8/3kV |